Innovative HPC® platform - a fundamentally new approach

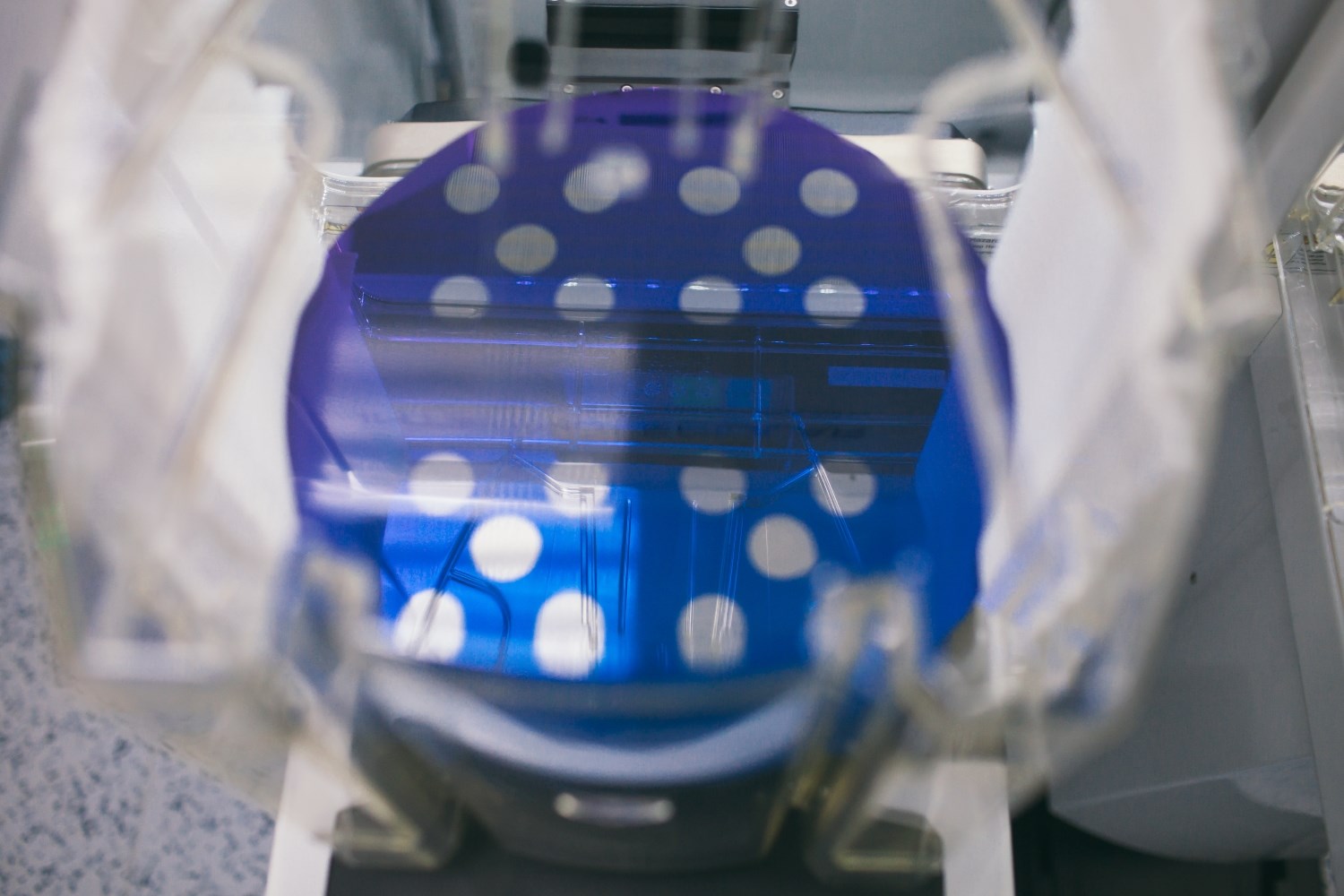

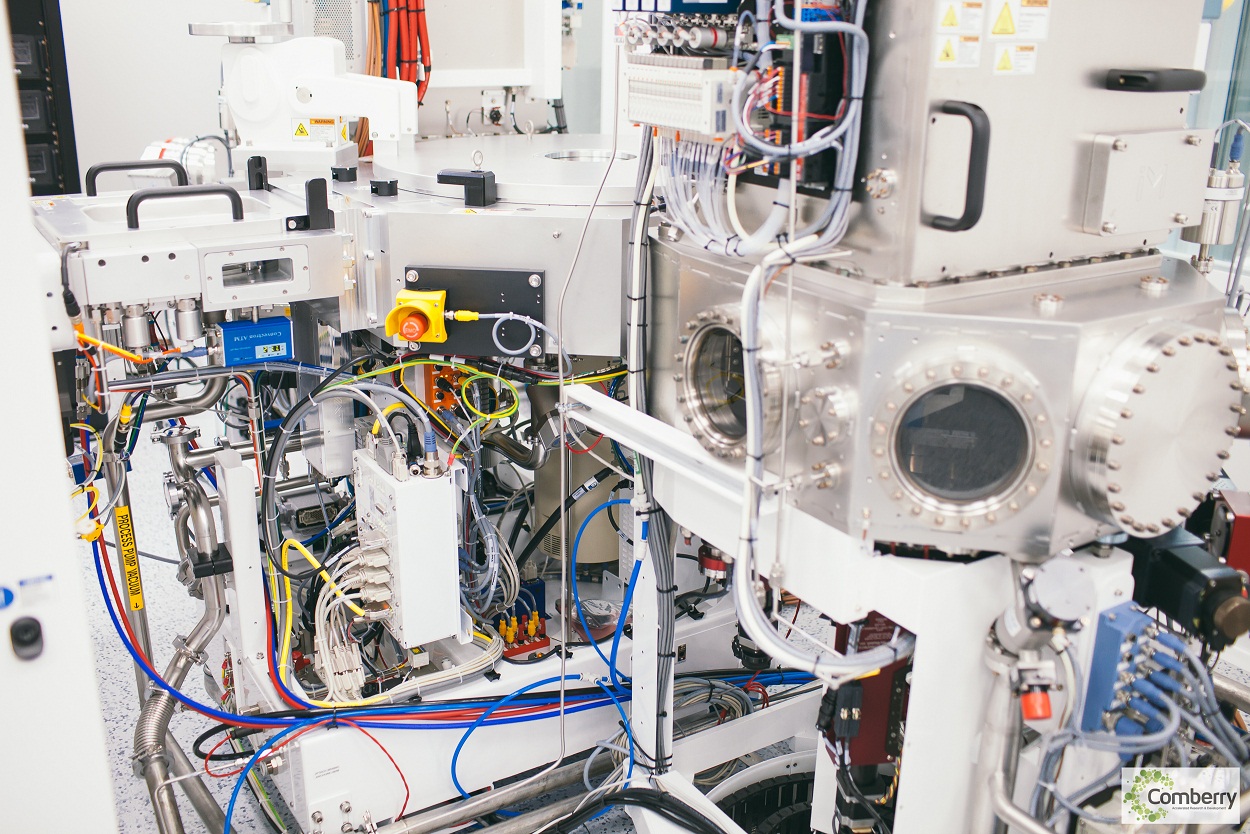

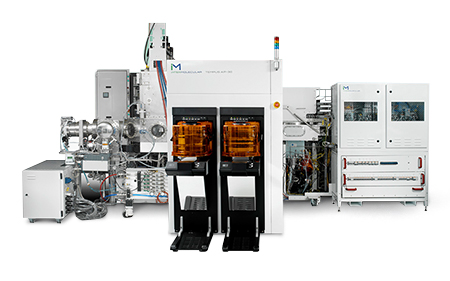

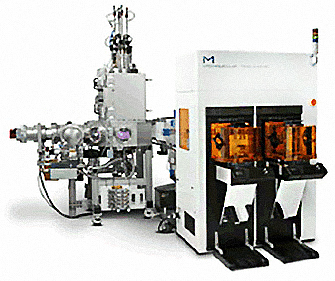

The Comberry™ platform combines software, technological and analytical equipment, and HPC® technology (HPC® technology makes it possible to conduct dozens and even hundreds of experiments simultaneously, thereby discovering the most high-performing materials and their application methods) developed by Intermolecular, Inc. (Intermolecular, Inc. is a research company established in 2004 in California. One of the company’s areas of expertise is creation of a combinatorial (HPC™) platform that accelerates scientific research, implements innovations, and substantially reduces time to market for new products in the semiconductor and clean energy industries.

Within collaborative development research programs (CDPs) implemented jointly with customers, Intermolecular, Inc. creates unique technologies focused on advanced materials and processes.

Intermolecular, Inc. was founded in 2004 in San Jose, California.

All rights to the trademarks “Intermolecular”, “HPC” and the logo of Intermolecular, Inc. are reserved and belong to Intermolecular, Inc.

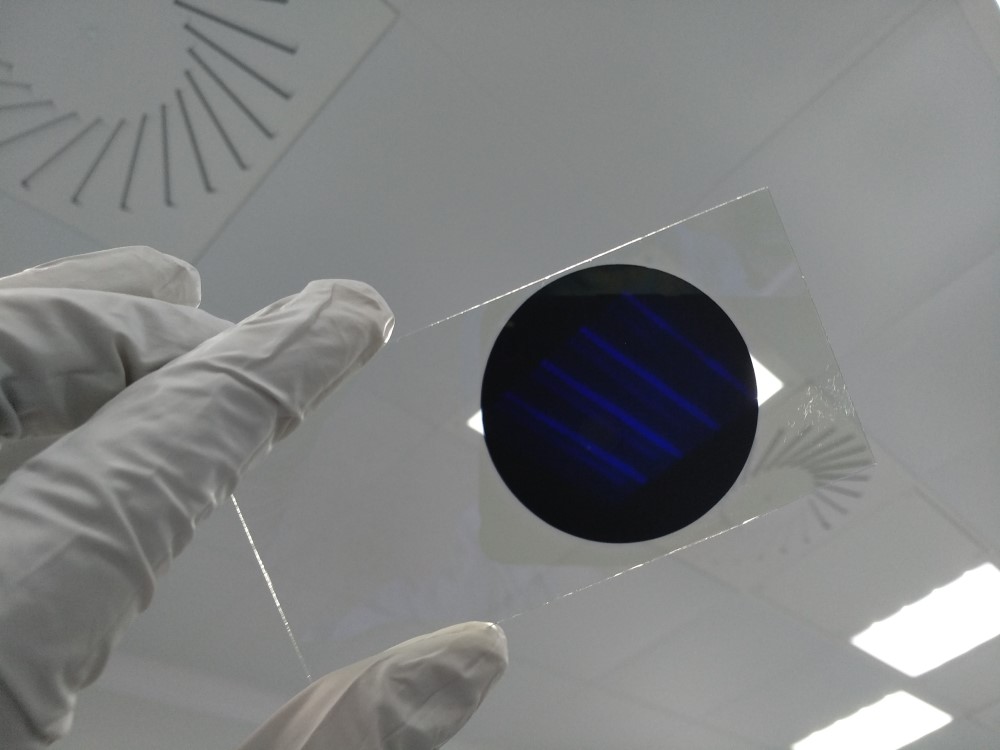

The platform gives the possibility to conduct groups of experiments simultaneously, the results are quickly studied with special analytical methods to determine the most promising materials and processes for fabrication of thin-film devices. Using the platform it is possible to scale up the scientific results from the labs for production.

Combinatorial technology for thin-film coatings multiplies research cycles and increases their efficiency, which in turn contributes to cost efficient and seamless implementation of innovative solutions to mass production.

The Comberry ™ technology platform is unparalleled in both Russian and European markets.

Innovative HPC® platform - a fundamentally new approach

A revolutionary approach for conducting research

A revolutionary approach for conducting research Creation of production facilities

Creation of production facilities Bringing new products to market faster

Bringing new products to market faster

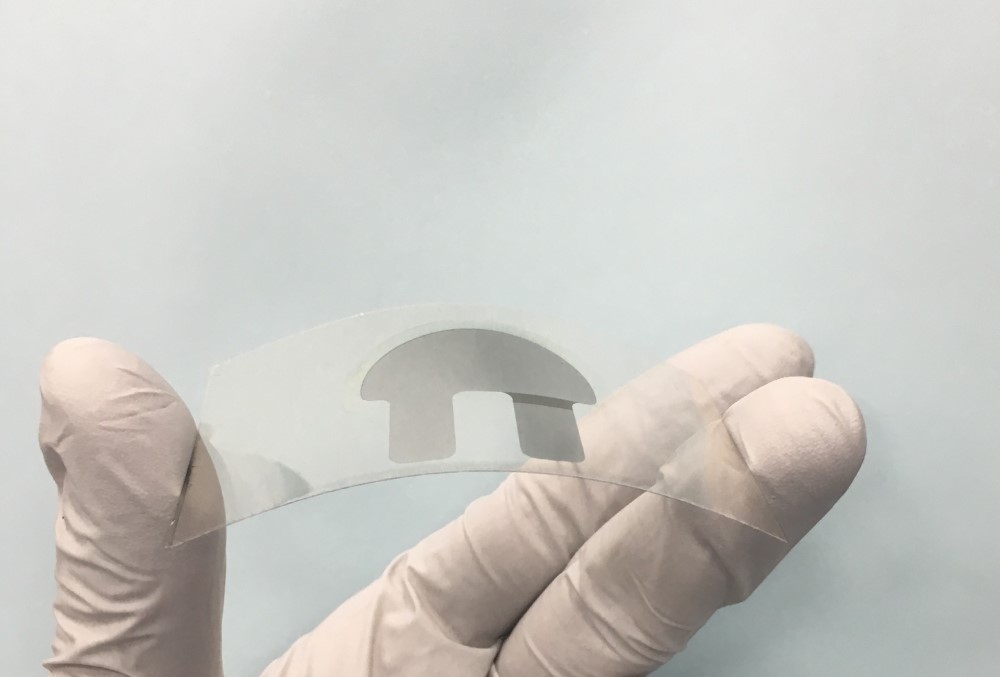

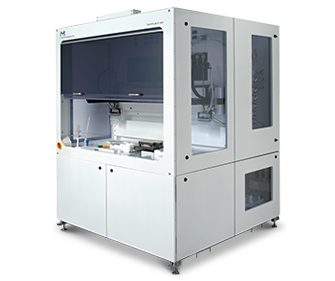

The unit facilitates studies of a wide spectrum of liquid-phase materials, for example, in integration of low-k and ultra-low-k dielectrics, liquid-phase surface cleaning prior to deposition of passivation layers as well as challenges of etching the excess material (thin-films) deposited as the result of technological process.

The unit facilitates studies of a wide spectrum of liquid-phase materials, for example, in integration of low-k and ultra-low-k dielectrics, liquid-phase surface cleaning prior to deposition of passivation layers as well as challenges of etching the excess material (thin-films) deposited as the result of technological process.